- 技術文章

LP-463PB-64-01熱沖擊試驗標準

2021-04-17 13:09:49 來源:上海鼎徵儀器儀表設備有限公司

參數 GMW15919 Ford BI 107-05 LP-463PB-64-01 流量 目標值2.7L/Min 目標值2.7L/Min 目標值2.7L/Min 樣品測試位置溫度 98-100℃ 98-100℃ 98-100℃ 油箱壓力 約50psi 約50psi 約50psi 動態壓力 目標值37.9Kpa(5.5Psi) 目標值37.9Kpa(5.5Psi) 目標值37.9Kpa(5.5Psi) 噴嘴和樣品距離 50-75mm 50-75mm 50-75mm 噴嘴和樣品角度 45° 45° 45° 噴嘴直徑 12.25 to 12.75mm 12.25 to 12.75mm 12.25 to 12.75mm 噴嘴長度 >100mm >100mm >100mm

THERMAL SHOCK PROCEDURE FOR ORGANIC COATING ADHESION TEST

涂層系統附著力測試的熱沖擊程序

1.0 GENERAL

Test procedure is designed to evaluate the adhesion of organic coatings.

測試程序旨在評估有機涂層的附著力。

1.1 Purpose

The purpose of this procedure is to determine the resistance to degradation and/or adhesion loss over steel, aluminum, plastic or other substrates coated with organic finishes while subjected to thermal changes and high pressure spray conditions. These conditions are similar to those generated by the heated pressure wash equipment found in manual car wash operations. Evaluation is based on a pass/fail analysis.

本程序的目的是確定在熱變化和高壓噴涂條件下,鋼、鋁、塑料或其他涂有有機涂層的基材的抗降解性和/或附著力損失性。這些情況與手動洗車操作中加熱壓力清洗設備產生的情況相似。評估基于通過/失敗分析。

1.2 Coverage of this Standard

This test procedure may be used to evaluate organic finishes over metal or plastic substrates with

appropriate surface preparation (plating, chemical surface treatment, etc). This test procedure can be used for interior, exterior, and underhood/underbody applications.

本試驗程序可用于評估金屬或塑料基底上的有機飾面,包括 適當的表面處理(電鍍、化學表面處理等)。本測試程序可用于車內、車外和發動機罩下/車身底部應用。

2.0 SPECIAL TEST EQUIPMENT & MATERIALS

專用試驗設備和材料TABLE 1: SPECIAL TEST EQUIPMENT Name Of Item Description Make/Model Scribe Tool

Straight shank tungsten carbide

tipped scribe device with a tip angle

of 60 15 degrees or equivalent.N.A.

Razor knife Common utility knife or X-acto knife N.A. Water Bath

Capable of maintaining 38 +/- 2° C

with aerationN.A.

Freezer Capable of maintaining -29 +/- 2° C N N.A. Steam Generator

蒸汽發生器Discharge Nozzle: 12.5 mm ID (100

mm minimum length)

Dynamic Head Pressure: 37.9 +/- 2

kPa (5.5 psi) +/- 5% deviationModel 100 Steam

Generator from Atomic Steam

Co., 10727 Fendell, Detroit, MI

48238 or equivalent.

3.0 SUMMARY OF METHOD

This procedure will evaluate organic coating adhesion after exposure to elevated and reduced

temperatures using high pressure steam impingement.

本程序將評估有機涂層暴露于高溫和低溫環境后的附著力使用高壓蒸汽沖擊的溫度。

4.0 SAFETY PRECAUTIONS

This test procedure involves high and low temperature conditions, steam, and high pressure spray.

Pressurized steam represents a potential burn hazard. Parts must be secured properly to the test fixture and laboratory technicians should wear full face shields and heat resistant gloves. If possible, the testing should be conducted in a test chamber equipped with a full closing front shield with safety interlock to prevent triggering steam with the shield open. This standard does not address all the safety problems associated with its use. It is the responsibility of whomever uses this standard to consult and establish appropriate safety and health practices to determine the applicability of regulatory limitations prior to use.

本試驗程序涉及高溫和低溫條件、蒸汽和高壓噴霧。加壓蒸汽有潛在的燒傷危險。零件必須正確地固定在試驗夾具上,實驗室技術人員應佩戴全面罩和耐熱手套。如有可能,應在配有全封閉前護罩(帶安全聯鎖裝置)的試驗箱中進行試驗,以防止護罩打開時觸發蒸汽。本標準并未解決與其使用相關的所有安全問題。使用本標準的任何人都有責任在使用前咨詢并建立適當的安全和健康實踐,以確定監管限制的適用性。

5.0 CONDITIONING

Condition fully cured parts or panels for a minimum of 72 hours at 23 +/- 2°C and 50 +/- 10% relative humidity prior to beginning test procedure.

在開始試驗程序之前,在23+/-2°C和50+/-10%相對濕度條件下對完全固化的零件或面板進行至少72小時的處理。

6.0 PROCEDURE

A. Immerse test specimen in an aerated water bath at 38 2°C for 4 hours. Water should contain max 5 ppm dissolved solids as sodium chloride (NaCl).

將試樣浸入38 2°C的充氣水浴中4小時。水應含有*多5 ppm的溶解固體,如氯化鈉(NaCl)。

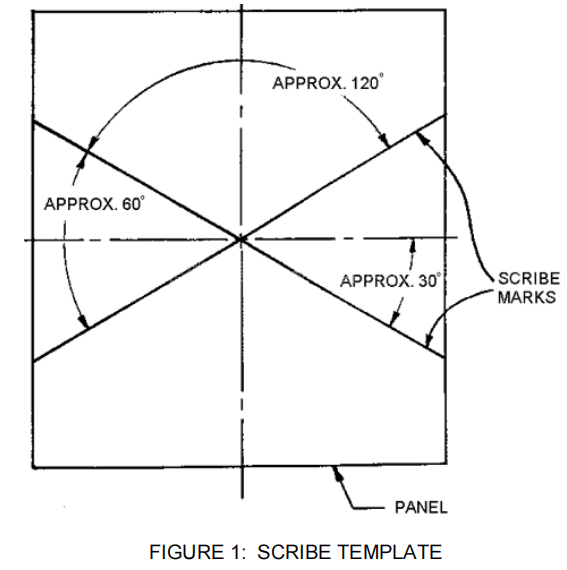

B. Immediately after removal from water bath, scribe parts or panels through to the substrate as shown in Figure 1.

從水浴槽中取出后,立即將零件或面板劃入基板,如所示

- Hard substrates such as metal or rigid plastic should use a carbide tipped scribe tool.金屬或硬塑料等硬基片應使用硬質合金尖劃線工具

- Elastomeric substrates should be scribed with a razor knife. 應使用剃須刀劃出彈性基底。

- Place parts or panels into freezer held at -29±2°C for a period of minimum 3 hours. 將零件或面板放置在-29 ±2°C的冰箱中至少3小時。

- Verify that steam generation equipment is functioning at a flow rate or 2.7 L/minute and dynamic head pressure of 37.9 kPa (5.5 psi) as detailed in the equipment section of this document. See Appendix A showing a suitable device for measuring dynamic head pressure. 驗證蒸汽發生設備在流量或2.7 L/min和動態壓頭壓力為37.9 kPa(5.5 psi)的情況下運行,如本文件設備部分所述。見附錄A,其中顯示了測量動態壓頭壓力的合適裝置。

E. Adjust test part or panel holding fixture and nozzle to provide the necessary 45° angle of impingement and the 50-75 mm nozzle to part distance required for testing.

NOTE: Steam impingement force requires that the part or panel be held tightly to prevent shifting during the test. Adjustable clamps are used to provide both necessary holding strength and part

adjustability.

調整試驗零件或面板固定夾具和噴嘴,以提供必要的45°沖擊角和50-75 mm噴嘴到試驗所需零件的距離。

注:蒸汽沖擊力要求緊緊握住零件或面板,以防止在試驗過程中移動。可調夾具用于提供必要的夾持強度和零件可調性。

F. Remove part or panel from freezer and immediately mount in the holding fixture ensuring that the nozzle is directed at the center of the “X” scribe. See Appendix B.

從冷凍柜中取出零件或面板,并立即安裝在夾具中,確保噴嘴指向“X”劃線的中心。見附錄B。

G. Begin 30 second steam impingement within 30 seconds of removal from the freezer.

NOTE: Pressurized steam represents a potential burn hazard. Parts must be secured properly to the test fixture and laboratory technicians should wear full face shields and heat resistant gloves. If possible, the testing should be conducted in a test chamber equipped with a full closing front

shield with a safety interlock to prevent triggering steam with the shield open.

從冷凍柜中取出后30秒內開始30秒的蒸汽沖擊。

注:加壓蒸汽代表潛在的燒傷危險。零件必須正確地固定在試驗夾具上,實驗室技術人員應佩戴全面罩和耐熱手套。如有可能,應在配有全封閉前護罩的試驗箱中進行試驗,前護罩配有安全聯鎖裝置,以防止護罩打開時觸發蒸汽。

- After 30 second test is complete, evaluate the test part for change in appearance or adhesion loss. 30秒試驗完成后,評估試驗零件的外觀變化或附著力損失。

7.0 REPORT

Record any changes in visual appearance such as cracking, whitening, blushing or discoloration, or loss of gloss.

If adhesion loss occurs, record the area of removal in cm2. Adhesion loss of < 0.5 cm2 is acceptable.

記錄視覺外觀的任何變化,如開裂、變白、發紅或變色或失去光澤。如果發生粘著損失,記錄去除面積(單位:cm2)。附著力損失<0.5 cm2是可以接受的。

8.0 DEFINITIONS/ABBREVIATIONS/ACRONYMS

cm: centimeters

kPa: kiloPascal

L: liters

mm: millimeters

psi: pounds per square inch

9.0 GENERAL INFORMATION

Three asterisks “***” after the section/paragraph header denotes single or multiple technical changes to the section/paragraph. Specific technical changes within a section, subsection, table, or figure may be highlighted in yellow.

Certain important information relative to this Laboratory Procedure has been included in separate

standards. To assure the materials submitted meet all of Chrysler requirements, it is mandatory that the requirements in the following standards be met.

CS-9800 - Application of this procedure, the subscription service, and approved sources

CS-9003 - Regulated substances and recyclability

For specific information on this document, please refer to the contact person shown in the "Publication Information" Section of this document. For general information on obtaining Engineering Standards and Laboratory Procedures, see CS-9800 or contact the Engineering Standards Department at LP-463PB-64-01, Change -, 2011-05-09, Page 3

新發布

-

產品搜索

留 言

- 聯系人:謝文清

- 電 話:021-32535039

- 手 機:13472521719

- 傳 真:021-32535039

- 郵 箱:xiewenqing@shdzyq.com

- 郵 編:201821

- 地 址:上海市嘉定區德富路1198號803室太湖世家國際大廈

- 網 址:

https://dingzhi1999.cn.goepe.com/

http://www.sgt151.com